Marine Structures, an Australian company, is making significant strides to enhance its presence in the Pacific region through strategic joint ventures and local partnerships aimed at expanding floating marine infrastructure. Last year, the company joined forces with Superior Jetties and Jetty Specialist, combining their 70 years of family marine experience to create a more robust business platform focused on the emerging markets of the Pacific Islands.

John Hogan, the Director of Marine Structures, emphasized the necessity of proactively developing business opportunities rather than waiting for orders. He stated, “There is a need to actively develop business rather than wait for orders, focusing on island nations with planned infrastructure.” This approach includes introducing innovative floating designs to complement traditional fixed structures, allowing them to cater to the unique needs of the region.

Central to their strategy is building relationships with local companies in Fiji, which they regard as crucial for improving delivery and installation capabilities. As part of this initiative, the company plans to gradually shift certain manufacturing tasks to Fiji, which would enhance local involvement and cost efficiency. Fiji’s geographic proximity to Australia, cultural similarities, and existing supplier relationships make it a strategic hub, reinforced by past successes in marina projects such as expansions at Denarau and luxury yacht facilities.

Hogan highlighted the logistical advantages of Fiji being just a three-hour flight from Brisbane, making it an ideal base for Pacific expansion. Current operations involve shipping pre-manufactured kits to trusted local installers, but future plans involve employing local staff for on-site positions as project demands increase. This effort is complemented by non-exclusive arrangements with local stakeholders to foster broader collaboration networks.

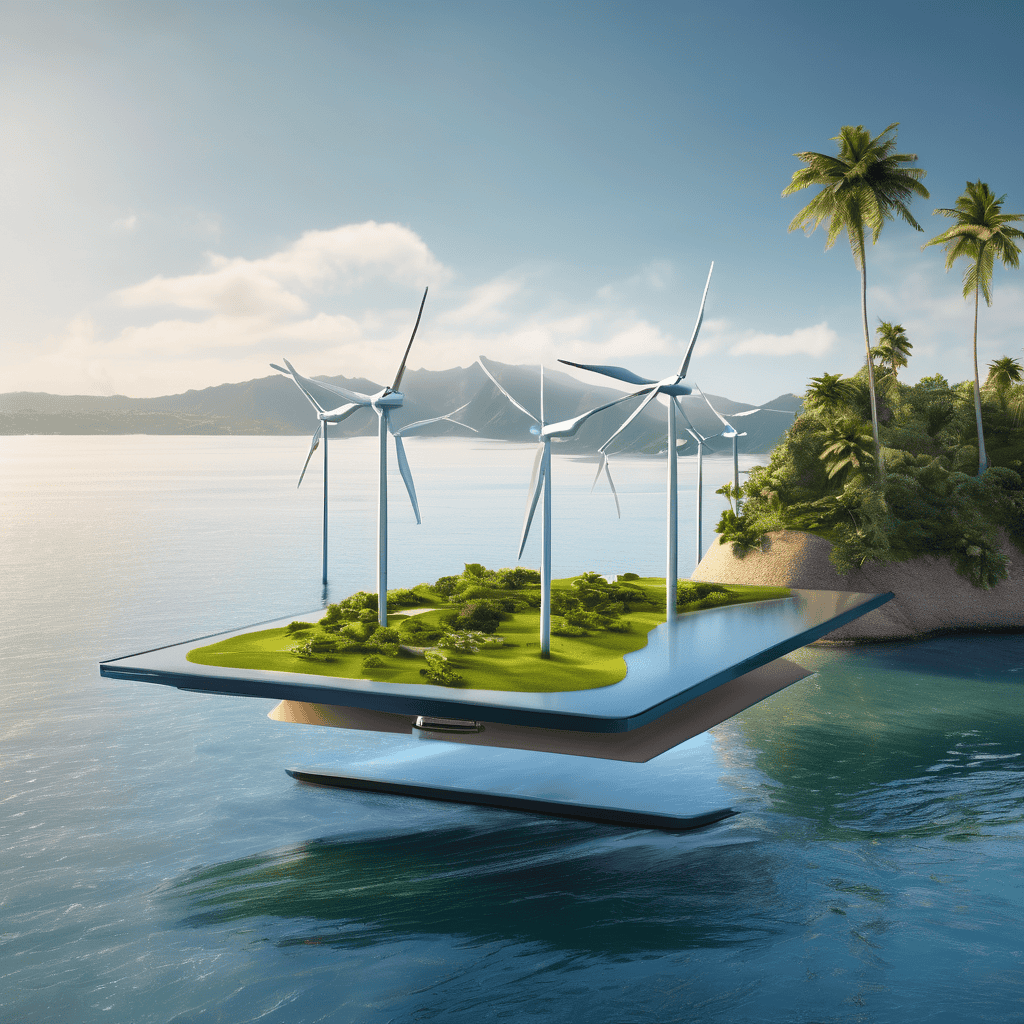

The floating marine structures are constructed for longevity and low maintenance while adhering to environmental responsibilities in line with the United Nations’ Sustainable Development Goals. Innovations such as fiberglass reinforcement and elastomeric hinges have extended the product’s design life from 25 to 50 years, significantly reducing maintenance needs. Hogan underscored the importance of sustainable materials like concrete, aluminum, and polyurethane, which lessen corrosion and extend the usable life of the structures, thereby minimizing lifecycle costs and environmental impact.

Marine Structures also integrates a sustainability framework that promotes “destination protection,” aiming to preserve marine ecosystems and prevent damage to coral reefs and mangroves. Compliance with Australian Standard AS 3962 for marina design ensures their products are resilient against cyclones and flooding—issues paramount to the region’s safety concerns.

Decades of exposure to cyclone conditions in Queensland have validated the durability of the company’s products, while the floating design provides additional seismic resilience through its subsea anchoring system. This feature is particularly vital in earthquake-prone areas, as it could lower project costs and mitigate risks compared to conventional fixed structures.

As Marine Structures continues to lead in the design and manufacturing of marine infrastructure, it is shaping the future of Australia’s waterways while contributing to sustainable and resilient development in the Pacific region.

Leave a comment